expertise

Specialists in stainless-steel wire components

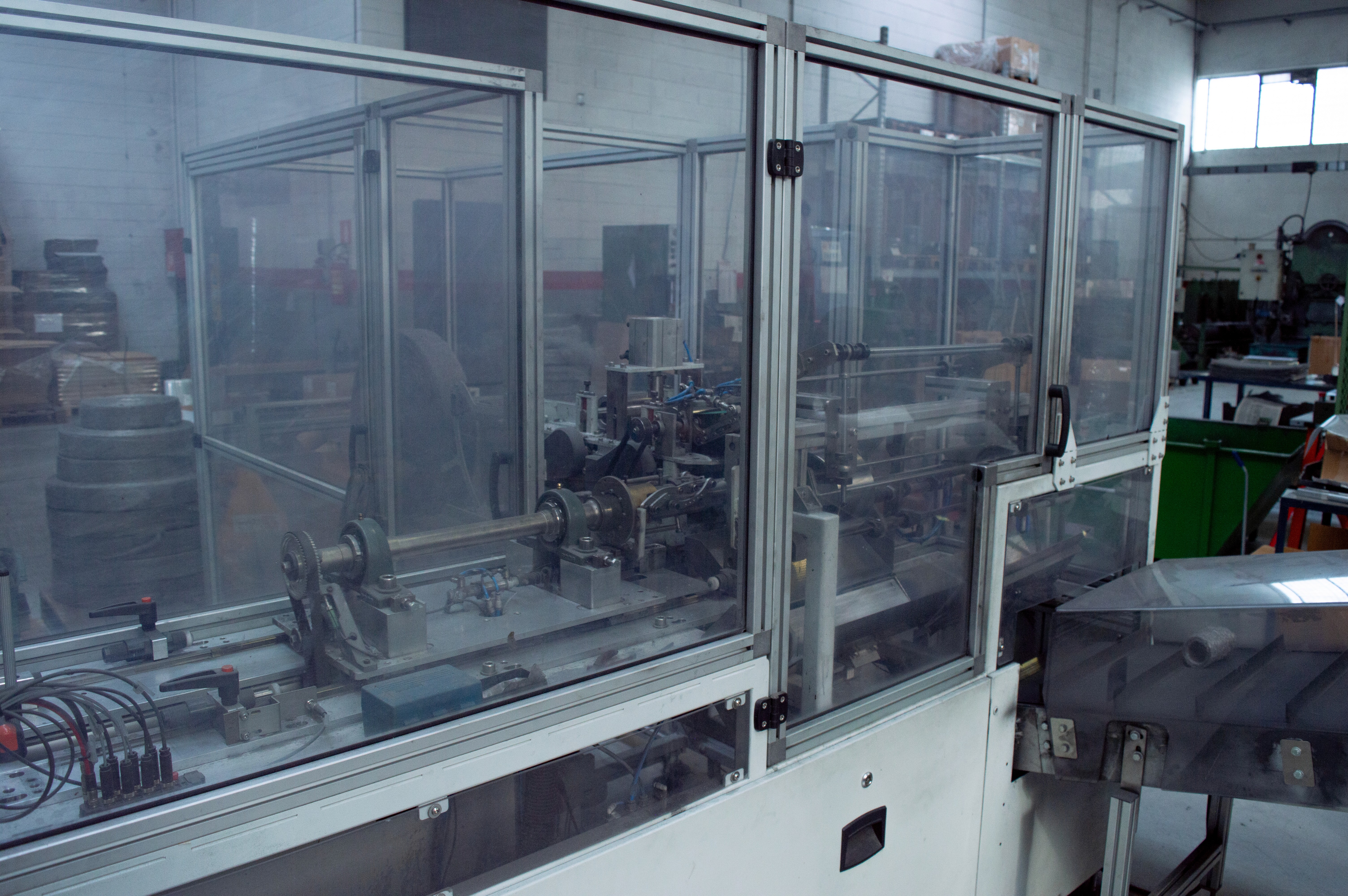

Executing Excellence, Enabling Innovation. Working with stainless-steel wires and fibers requires specialized knowledge, precision, and process control capabilities that few manufacturers have mastered. At Temas Technologies, we have transformed what is often a manual, craft-based activity into a controlled industrial process.

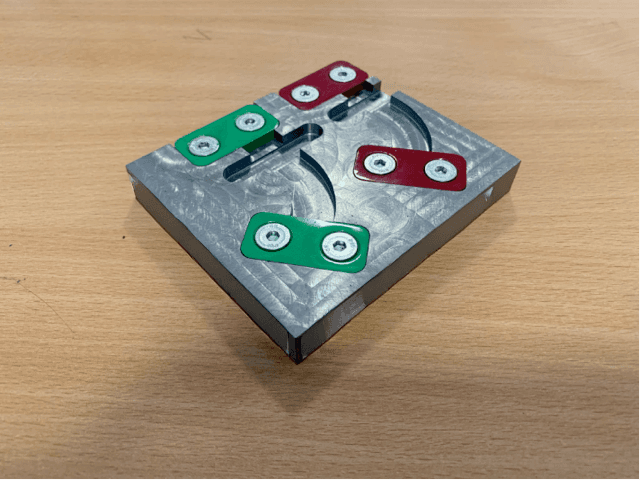

Through advanced forming technologies, dedicated tooling, and in-house engineering support, we design and produce high-performance components such as knitted wire meshes, steel wool elements, and complex wire assemblies.

Our experience allows us to manage material density, geometry, and performance with industrial-grade repeatable accuracy, delivering reliable solutions for demanding industrial environments.

Unseen but essential: this is how we create value beyond the design.